Hydronics

HYDRO-AIR SYSTEMS HAVE BEEN AROUND

for a long time…even hydro steam.

I remember the first time I saw a radiator

mounted inside of a plenum and I thought

“what the heck is this?” Back in the day,

when fresh air was deemed a necessity

(unlike today in our tight energy efficient

homes - ha!), ductwork would draw air

from the outside and heat it with these

duct-mounted radiators before delivering it

to the living space.

Not very efficient, but fuel was a lot less

costly back then, and the owners of these

homes weren’t shy of a few pennies. Times

have changed, however. Today when we

say hydro-air, we think of air handlers with

internal coils for heating and/or cooling.

VARIETY PACK

For the most part, hydro-air is a product

of the electric conversion market, when

electricity prices started to rise. Replacing

that old electric furnace and installing a

boiler with an air handler allowed versa-

tility when it came to zoning and potable

hot water.

Indeed, the ability to run additional

emitters off the boiler often led to systems

with multiple heat delivery schemes such

as warm air, convection and radiant. Entire

sections of the home could be heated by a

different medium, e.g. warm air upstairs;

radiant downstairs; baseboard in the base-

ment. And all of this with air conditioning

and endless hot water as well. The more

recent decades have seen an increased

demand for air conditioning, and for homes

heated with water, hydro-air is a very con-

venient solution.

One of the major differences between

air handlers and direct fired furnaces is the

quality of the air delivered to the home.

The heat exchangers in fuel-fired furnaces

are subjected to extremely high surface

temperatures, which tend to dry out the

delivered air. Whereas, with an air handler,

the heat exchanger never sees temperatures

above 180°F resulting in a much more

comfortable living environment.

INTRODUCING VARIABLE SPEEDS

The implementation of ECM technology

inHVACmotors has had a significant impact

on the efficiency of the equipment. We first

began to see ECM motors in air handlers

and condensing furnaces, which resulted

not just in increased motor efficiency but

also enhanced the performance of the

blower by compensating somewhat for

inadequate duct design. ECM motors make

a lot of sense for air handling equipment

because of the larger size motors needed to

move large volumes of air.

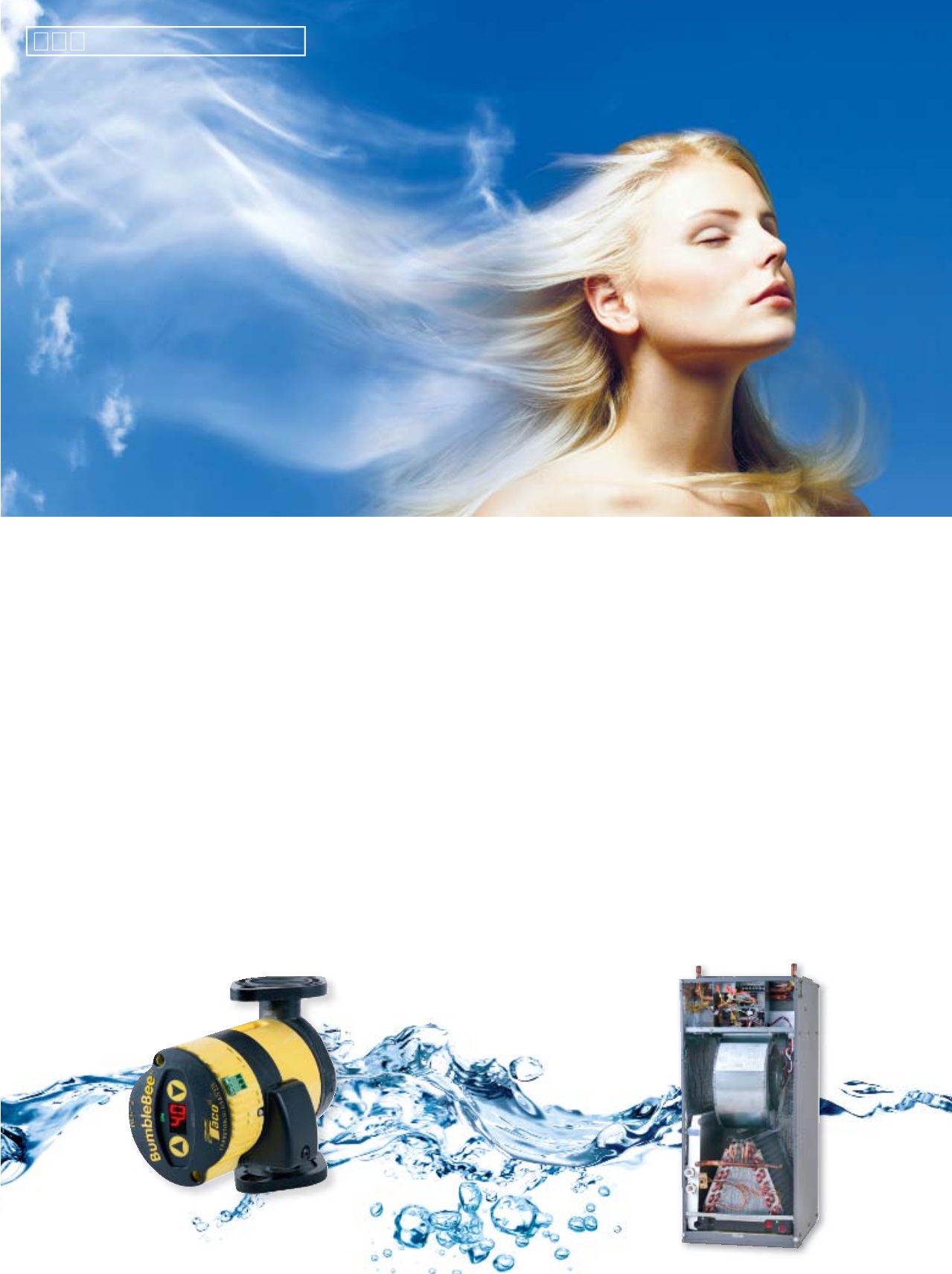

And more recently, we have seen the

introduction of ECM motors into the wet

side of the equation. All of the leading

pump manufacturers boast ECM circulators

- which begs the question of how best to use

this technology in a hydro-air application.

High-Performance

Hydro-Air

Variable Speed Motors Improve

Delivery of Conditioned Air

By Bruce Marshall, Emerson-Swan

22 • OIL

&

ENERGY

The Taco BumbleBee (Model

HEC2) is a programmable

circulator that uses Delta T

to increase efficiency and

improve comfort.

A Suntherm air

handler with heating

and cooling coils.