20 • OIL

&

ENERGY

Fuel Storage

Industry’s Approach on Tanks Is Much Improved

NORA program helps companies avoid excess liability from spills and tank ruptures

By John Levey, Oilheat Associates

WE’VE COME A LONG WAY!

In 2003 the National Oilheat Research

Alliance (NORA) embarked on a program

to assure that fuel oil storage tank systems

were properly installed and maintained.

The program was developed in conjunction

with the Institute for Business and Home

Safety (IBHS). IBHS is an organization

of insurers and reinsurers that conducts

research to identify and promote effective

actions that strengthen homes against

various causes of loss.

The NORA/IBHS “partnership” led to

the formalization of NORA’s Advanced

Oil Tank Program including the textbook

Fuel Oil Storage Tanks, Guide for Quality

Installation and Maintenance

, as well as

several videos and a full-day seminar.

Some in our industry questioned the

need for NORA to get involved in the

project, but let’s be serious: Our industry

doesn’t exist without tanks. And once NORA

got involved, many people felt that we did

a fairly good job of minimizing insurance

claims (and customer inconveniences) due

to oil tanks.

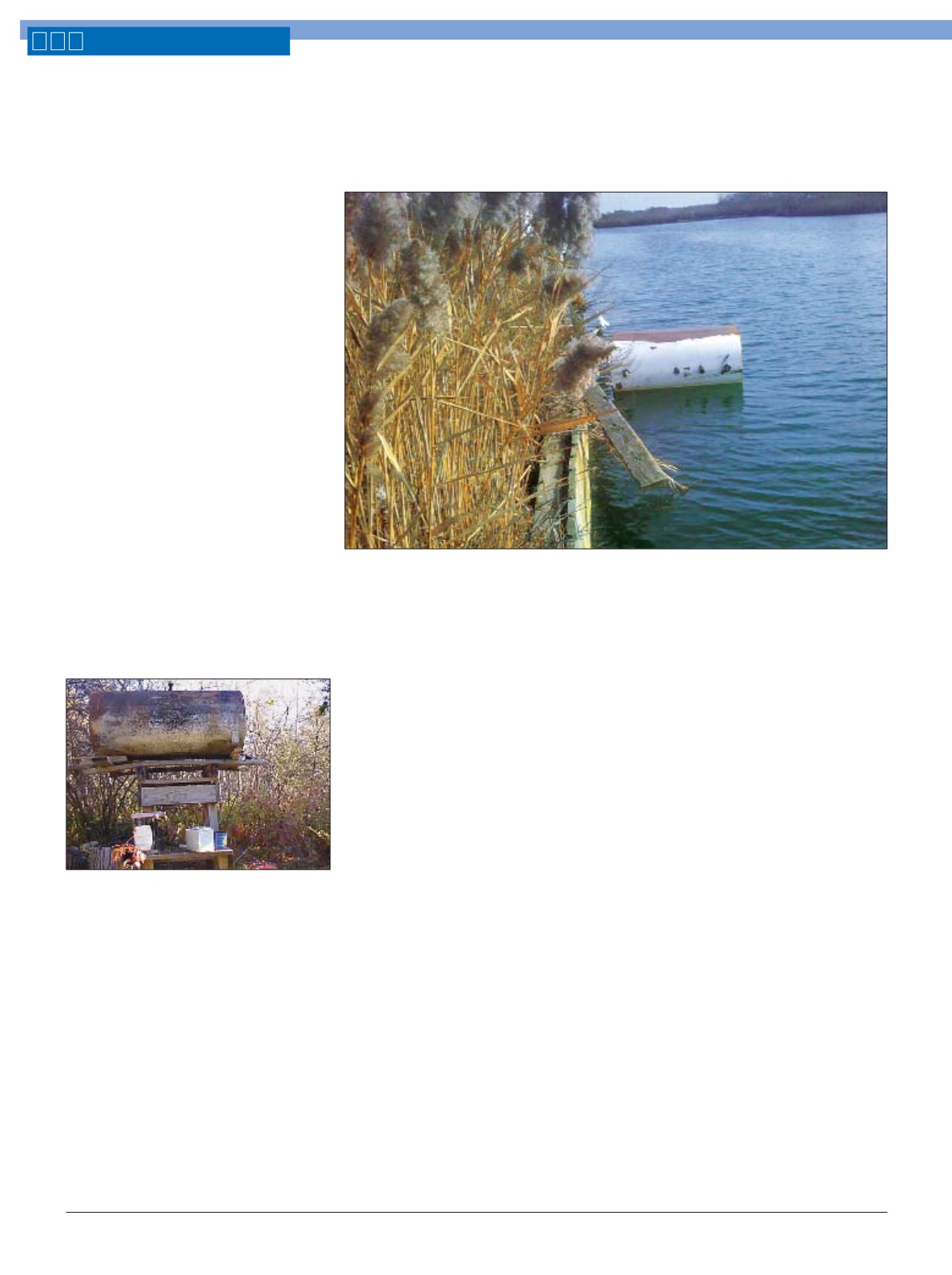

The picture above became the rallying

point of the program. When it was shown

to those attending sessions of NORA’s

tank seminar, most participants said their

companies would not consider delivering

to a tank as precariously located as this

one. Unfortunately the tank was in service

when the picture was taken, so someone

was delivering to it. Thankfully, it seems

like the industry as a whole has updated

its standards, and we haven’t found anyone

who would deliver to this tank today.

BETTER TANKS AND INSTALLATIONS

During its tenure, NORA has worked

closely with tank manufacturers, Under-

writers Laboratories (UL) and the National

Fire Protection Association (NFPA) to

improve the quality of tanks and their

installation procedures.

One of the most obvious changes we’ve

seen is that tank warranties have been

extended from the standard one-to-three-

year warranty available on most tanks in

the 1990s. Today we have warranties of 10,

20 and 30 years available, and some tanks

include insurance to cover oil spills.

We’ve also noticed an increase in the

number of “premium” tanks that are being

installed. These tanks are the double-wall

polyethylene/steel tanks; coated steel tanks;

double bottom steel tanks; single- and

double-wall fiberglass aboveground tanks;

etc. It is very encouraging to see that, as an

industry, we’re explaining the advantages

of these tanks and helping our customers

choose upgraded equipment in many situ-

ations.

Another change we’ve noticed is that

more and more companies are following

NORA guidelines regarding tank inspec-

tions. These companies closely follow

NORA’s recommendations regarding each

of the following.

• Initial inspections:

Performed before a

company delivers to a new tank or to a

new customer for the first time. These

comprehensive inspections include the

tank, oil lines, filters, fittings, etc. Before

NORA recommendations were released

many companies simply took a call from

a customer looking for a delivery and

sent a truck out to make the delivery

without checking on the condition of

the tank. In some cases, the customer’s

previous oil supplier had refused to

continue making deliveries because the

tank was in bad shape. The new company

making the delivery then got stuck with

the liability when a spill occurred.

• Routine inspections:

NORA recom-

mends that routine inspections be

performed during each tune-up, or

anytime that more than 12 months has

passed since the previous inspection.

These inspections don’t take long –

basically the technician makes sure

that nothing has changed since the last

inspection that could compromise the

safety of the system.

• Pre-delivery inspections:

These

inspections are limited to what the oil

driver can see from the delivery point.

The driver is not expected to go into

the house to look at the tank, oil lines,

etc. Rather, this inspection is intended

for the driver to make sure he or she

is at the right house and the right fill,

that the outside tank is in good shape,

that the fill and vent pipes and caps are

satisfactory, etc. In addition, NORA’s

no whistle – no fill recommendations

are emphasized in the written instruc-

tions for this level of inspection.

Overall, the companies that have fol-

lowed these guidelines report that they

The NFPA-31 Committee might

Update the Fire Code to require

that tanks be tied down so they

do not float away in floods.