November 2013 • 27

Biodiesel

Leveraging the RFS for Success in Home Heating

Biodiesel producer and Bioheat dealer find success with renewable energy

By Jenna Higgins Rose, for the National Biodiesel Board

ROBERT KUHSEL SAYS HE DIDN’T WANT TO

end up an old man on a barstool crying into

his beer over what might have been. At one

time a high school shop teacher, he decided

it was time for a dramatic career change.

“What motivated me was that I was not

happy with foreign oil and tired of sup-

porting it,” Kuhsel said. “I said ‘I’m going to

do something about it.’ This is what I did.”

What he did was take a leap of faith

into the biodiesel business. Having gained

exposure to alternative energy as a school

administrator for Amity Regional in

Woodbridge, Conn., he started looking

into biofuels and decided biodiesel made

sense. In 2008, during a dark chapter of

biodiesel history when many others were

leaving the business, he and his partner

saw opportunity. They broke ground on

White Mountain Biodiesel, LLC, in North

Haverhill, New Hampshire.

The company has produced biodiesel

for about three years, focusing on selling

into the fuels and Bioheat

®

market in New

Hampshire, Massachusetts and Vermont.

To ensure a quality product, each batch is

tested in-house, and an independent labo-

ratory does random sampling.

While the business is successful today,

employing about 20 workers, the road has

had a few rough spots.

THE RFS ROAD

One of those rough spots came with the

implementation of the federal Renewable

Fuel Standard (RFS), which sets modest

minimum requirements for the blending

of renewable fuels in the American fuel

supply. With the capacity to produce 3 mil-

lion to 4 million gallons per year, the plant

is classified as a small producer. That made

selling RINs, the credits used to fulfill RFS

obligations, a challenge.

“We felt a bit like prey as a small pro-

ducer,” Kuhsel laments. “When we went

to sell our RINs, obligated parties weighed

their risk/reward in working with us, and

ultimately we had to sell at a discount

because of our size.”

Those trying times in the early stages of

the RFS have turned around, thanks in part

to the RIN Integrity Task Force set up by the

National Biodiesel Board to look for viable

solutions to build confidence in RINs for all

involved. Now there are several options for

producers of all sizes to validate their RINs,

thus enabling them to earn full market value.

White Mountain opted to use third-

party vendor Genscape to validate the

plant’s RINs through the new EPA-approved

Quality Assurance Plan program. The QAP

is a voluntary program with the objective

of providing a more structured means to

make sure RINs entering the marketplace

are generated in a manner that insures

their validity for obligated parties. White

Mountain sells its B99 biodiesel to local

petroleum dealers who then delegate them

back to the company, which they then sell

to one or more obligated parties.

“I would say enthusiastically that the

system is working for us,” Kuhsel said.

“There are other systems as well, but this

was the best one for us.”

THE BOURNE IDENTITY

One of White Mountain’s customers is

Bourne’s Energy, a 66-year-old distribu-

tion business that began offering biodiesel

and Bioheat about three years ago. Based

in Morrisville, Vermont, the company

has locations and customers throughout

Northern Vermont.

Peter Bourne, president, says the com-

pany’s identity has changed with the addi-

tion of biodiesel. He uses the Bioheat logo

on his trucks, signs and marketing materials

for his oilheat customers. About 85 percent

of the company’s biodiesel business is for

the home heating oil market, and the rest is

for the on-road market.

“New England has a tendency to prefer

sustainable, green products, and our cus-

tomer base fits into this,” Bourne said. “We

wanted to differentiate ourselves from our

competitors.”

Bourne says his customers like the fact

that he offers a clean and renewable energy

source, and there have been no complaints

regarding the low blends of biodiesel used

in their applications.

Continued …

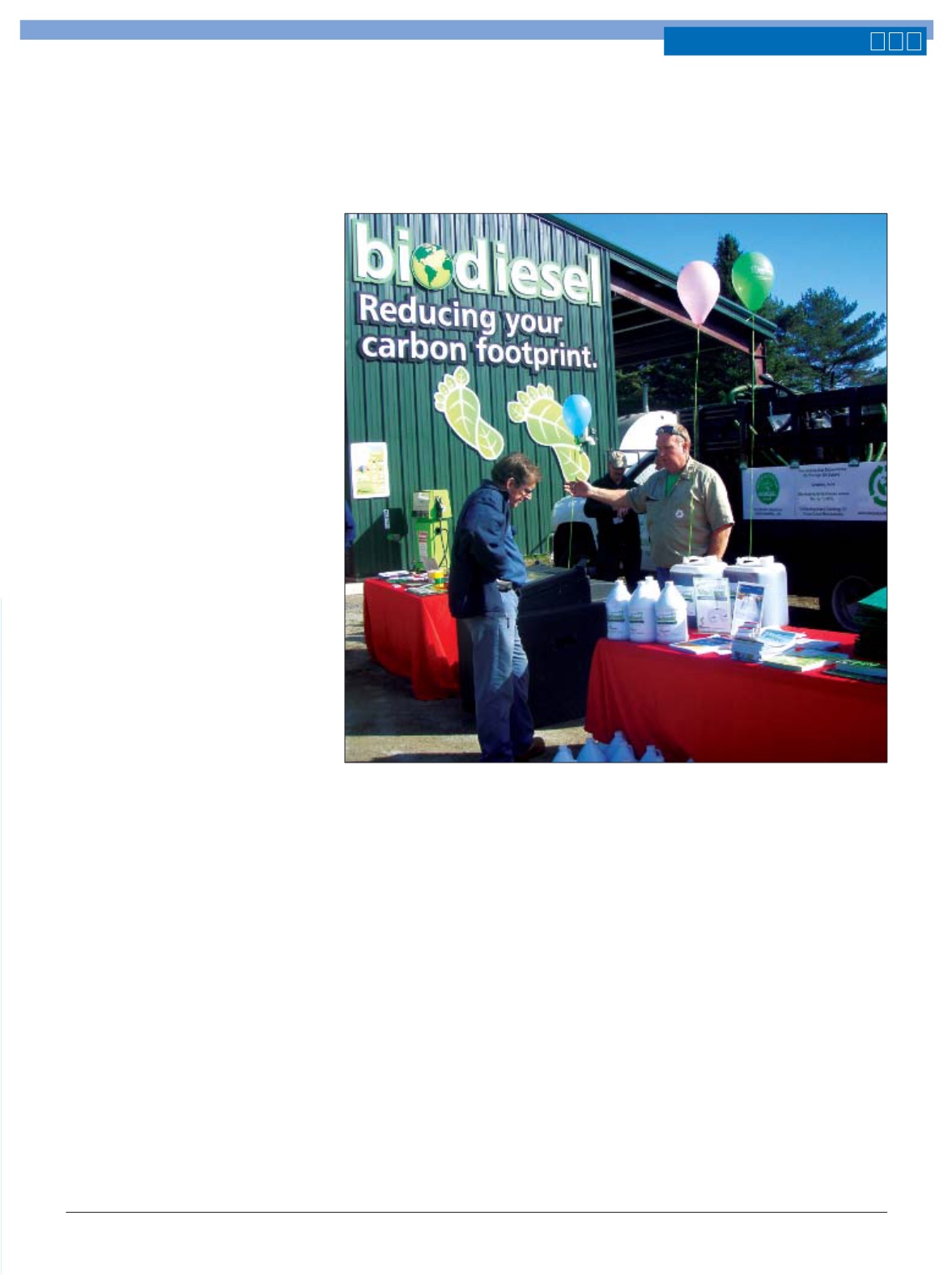

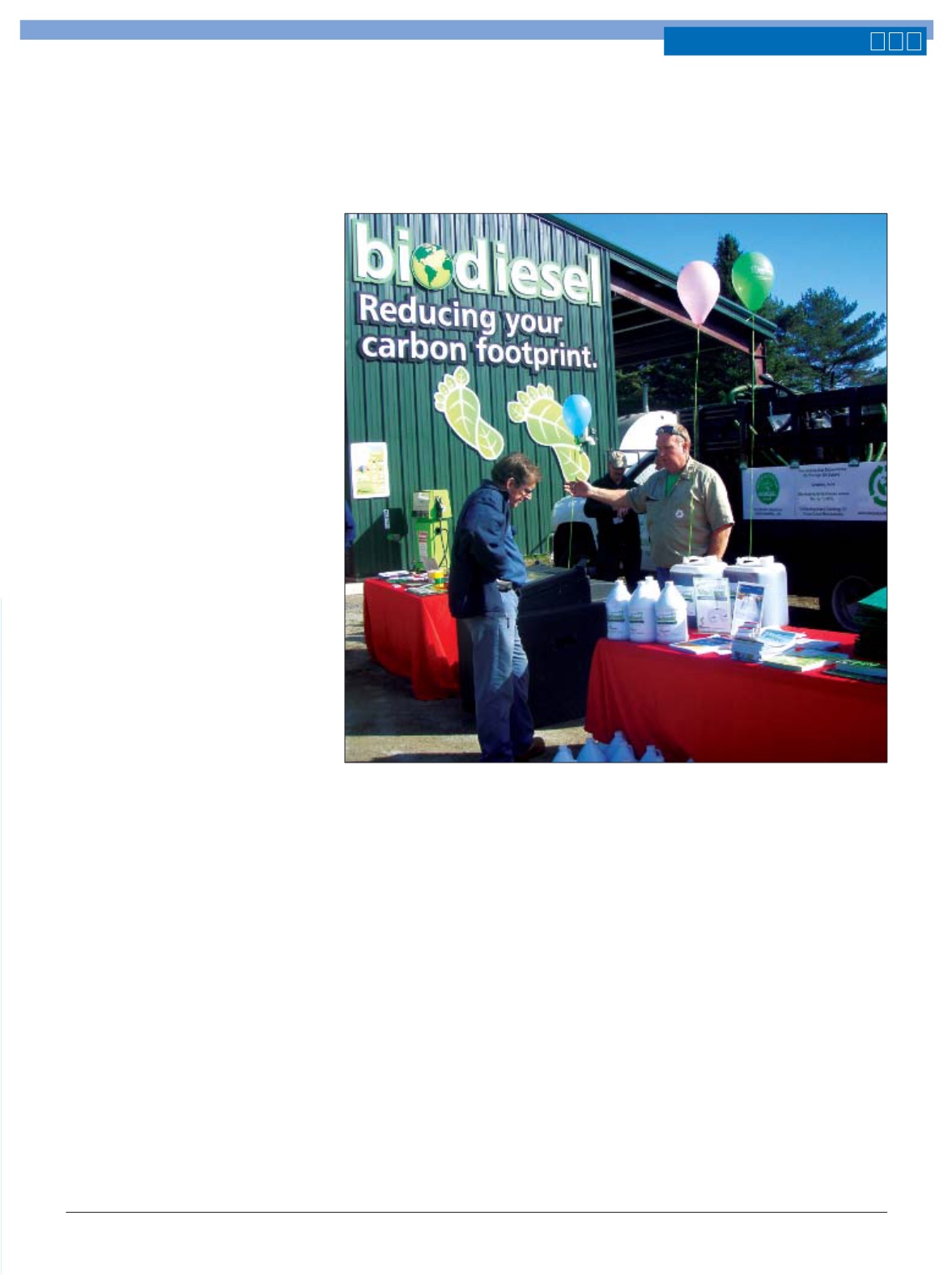

The grand opening of the

Bourne’s Biofuel Blending

Plant in Morrisville, Vermont.